Boost Your Productivity

by Up to2x*

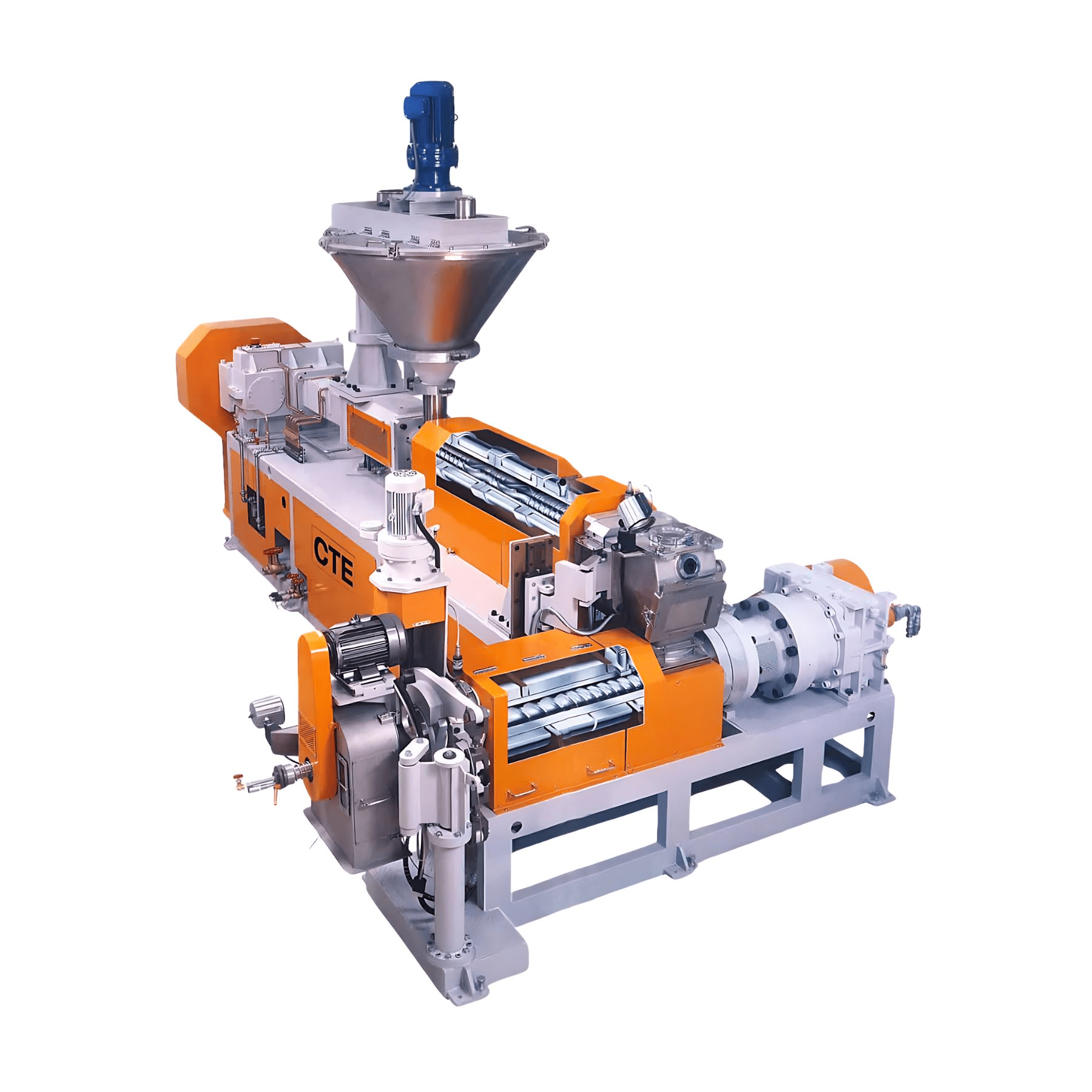

Transform Plastic

Processing Efficiency

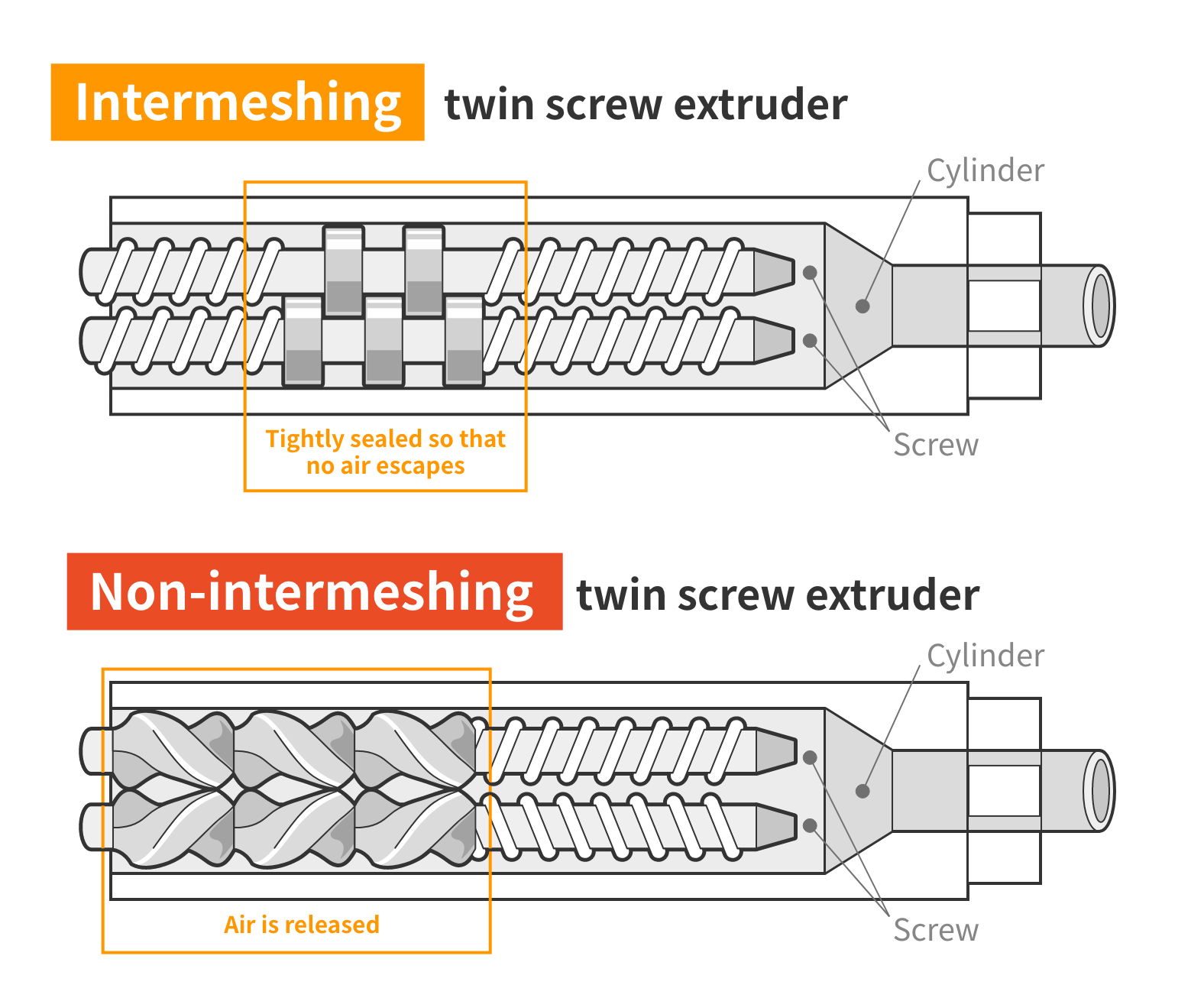

Twin-Screw Extruders:

with CTE’s advanced twin-screw extruder technology.

If you're a factory manager seeking to improve profitability, now is the ideal time to invest in next-generation extrusion equipment.

This site is operated by Zenken Corporation and sponsored by CTE Corporation.