Comparison of twin-screw extruder and single-screw extruder

Extrusion is a processing method that enables continuous forming of resins and composite materials, and is utilized in many manufacturing sites. This article compares the differences in structure and performance between single-axis extruders and twin-screw extruders, which are typical equipment indispensable for extrusion molding, and summarizes their respective characteristics and points to consider when selecting one.

Basic Structure of Extruder

An extruder is a device that heats and plasticizes resins and various materials and continuously extrudes them into desired shapes. A screw is mounted inside the machine, and heat generated by a heater or shear melts and blends the material while conveying it toward the extruder outlet.

Because of its ability to process continuously, it is an indispensable piece of equipment for manufacturing sites that demand efficiency. Note that extruders differ in the number of screws and structure,Single Screw" and "Twin ScrewThe two main categories are

Difference in structure and operating principle

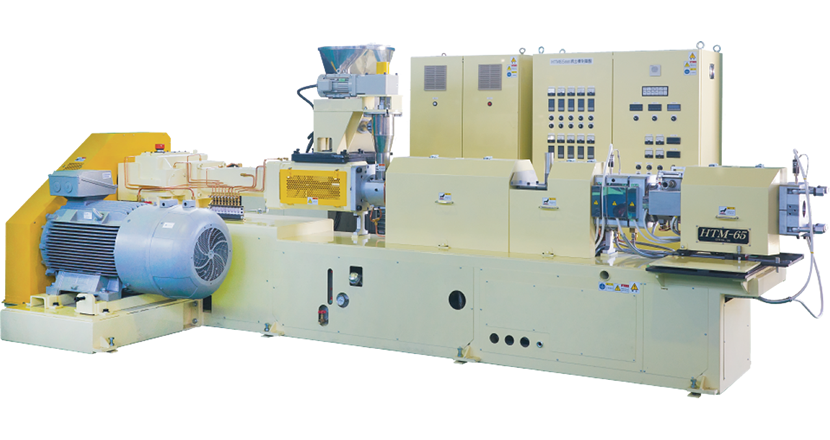

Structure and Mechanism of Single Screw Extruder

A single screw extruder conveys, heats, and kneads raw materials while a single screw rotates in the barrel, and extrudes them from the die as molded products. The equipment mainly consists of a feeder that supplies raw materials, a barrel, a screw, a temperature controller, a motor, and a cooling system.

The configuration of all extruders is almost the same, but the shape of the die must be changed according to the product to be molded. The structure is relatively simple,Simple product processingIt is widely used for

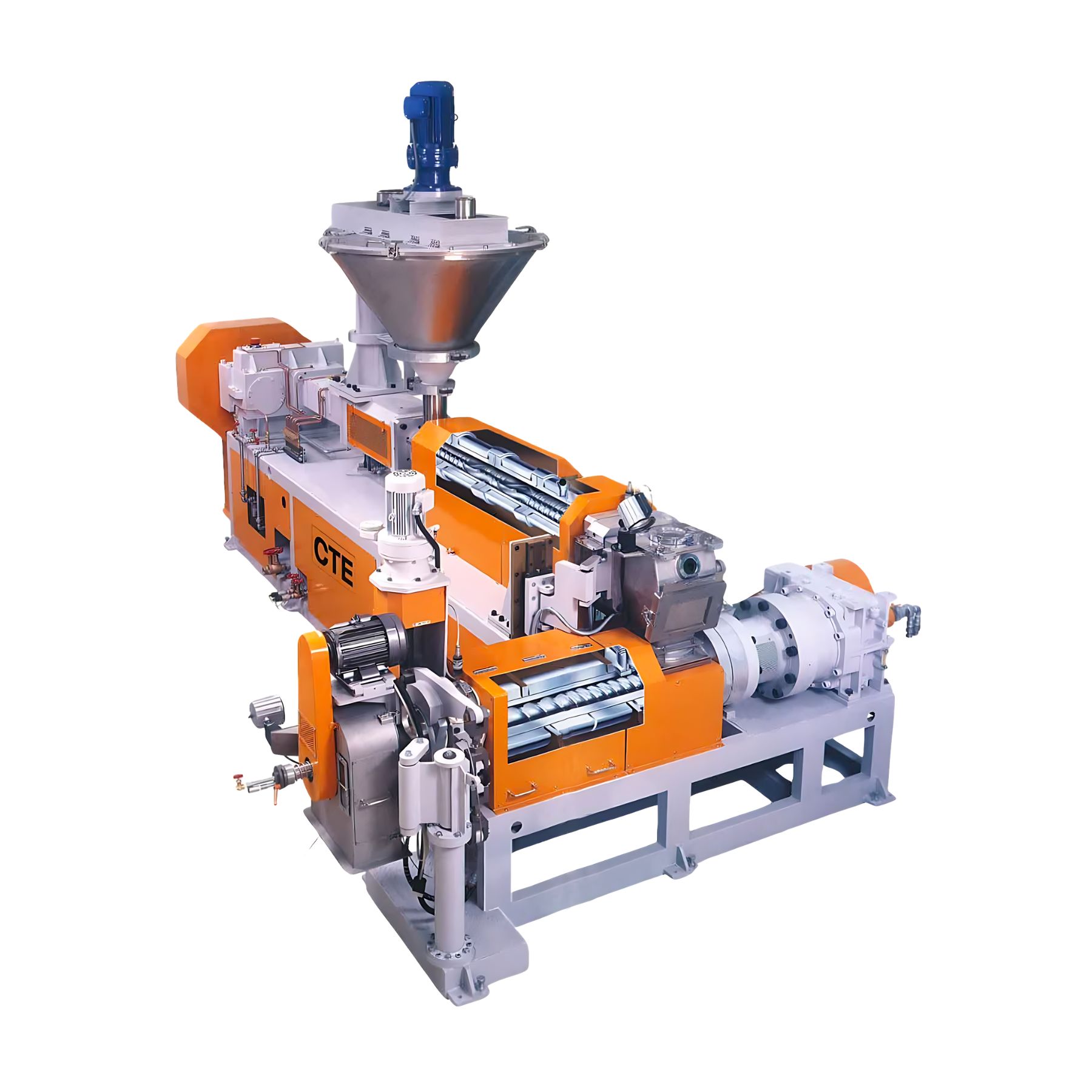

Twin Screw Extruder Structure and Mechanism

A major structural feature of the twin-screw extruder is that the two screws rotate in the same or opposite directions, enabling high kneading and shearing performance while conveying the material. The "meshing structure" in which the screws engage each other improves shearing, dispersion, and devolatilization (degassing) performance, enabling homogeneous material processing.

In addition, the screw is segmented, allowing the equipment to be customized according to the application and purpose.Molding of complex formulations and high-performance materialsSuitable for

Comparison Table: Differences by Item

| Company Name | Single Screw Extruder | Twin-Screw Extruders: |

|---|---|---|

| Number of Screws | one (object) | two (long cylindrical things) |

| structure | simple | High complexity and configuration flexibility |

| initial cost | low ball (baseball) | high |

| operability | easy | Requires proficiency |

| kneading property | low-born | High (high shear) |

| Devolatilization performance | limited | Superior (frequent surface updates) |

| Self-cleaning | low ball (baseball) | High (low residue) |

| productive capacity | Medium to low | High (high throughput) |

| Material adaptability | Pellets of resin, etc. | Compatible with powders, composite materials, and heat-sensitive resins |

Suitability Comparison by Application

Applications suitable for single screw extruders

Productions for which the use of a single-screw extruder is suited include PVC, PE, and PP.Pipe Extrusionare some examples. In addition, single-axis extruders are also widely used for profile molding for building materials and general film and sheet molding. The simplicity of the equipment configuration enables stable performance in production lines where the process is relatively simple.

Applications suitable for twin-screw extruders

The twin-screw extruder has high mixing and devolatilization performance, and therefore can be used to produce masterbatches, additives, CaCO₃, glass fibers, etc.Homogeneous dispersion and mixing of high filler materialsIt is suitable for It can be adapted to complex processes involving reactive extrusion and chemicals, as well as materials with low thermal stability such as PVC and pharmaceutical materials.

They are also used in diverse fields such as molding of recycled materials and foams, PET recycling, and extrusion molding of food and pet food, where high-performance kneading, devolatilization, and control are required.

Selection Points at the Time of Introduction

Complexity of the product to be manufactured

For the production of molded products with simple shapes and functions, a single-screw extruder with a simple structure is sufficient. On the other hand, for products that require blending of multiple raw materials or material modification,Twin-screw extruder with high kneading performance and configuration flexibilitySuitable for.

Material Properties

The type of extruder to choose depends on the material properties. If pellet material is the main material, a single screw extruder is more cost-effective.Complex raw material compositions, such as those involving the addition of powders and fillersA twin-screw extruder with excellent homogeneous mixing and stable conveying is effective for

Production volume and throughput

For a line focusing on small to medium-lot products, an easy-to-handle single-axis extruder is more efficient. Conversely, for a stable mass production system,High throughput can be achievedTwin-screw extruders tend to be the choice.

Technical resources and training costs

Single-axis extruders are relatively easy to operate and can be easily introduced by novice operators or a small number of operators. On the other hand, twin-screw extruders have complex equipment configuration and condition settings, so it is desirable to have an experienced person who is familiar with extruders or an environment where sufficient resources are available to learn the technology.

CTE's twin-screw extruders combine high mixing, dispersing, and degassing performance,Compatible with complex compounded materials, recycled materials, and high filler compoundsThe flexibility of this product is its ability to be used in a wide range of applications. It is suitable for sites where both quality and productivity are required, as it ensures stable physical properties while minimizing burns and agglomerations.

It is also directly linked to reduction of material loss and review of raw material costs, and contributes to improvement of the profit structure of the entire production line. When considering the introduction of a twin-screw extruder, please consider CTE, which is backed by our proven track record and technical capabilities.

summary

Single-axis extruders are simple in structure, easy to operate, and can be introduced at low cost. Twin-screw extruders, on the other hand, offer high kneading performance and material adaptability, and can handle complex products and mass production. Single-axis and twin-screw extruders have different advantages and limitations,Different uses are required for different purposes..

When introducing a new machine, it is important to select one that matches the company's production plan and technical resources from multiple perspectives, including initial cost, kneading performance, production capacity, range of materials handled, as well as engineer proficiency and compatibility with the production system.