Material processing to reduce molding defects in plastics

Molding defects that occur in plastic processing are largely attributable not only to molds and molding conditions, but also to raw material processing. By reviewing the raw material mixing process, it is possible to expect a significant improvement in the percentage of good products. Here, we introduce the types of molding defects and measures to deter them by utilizing twin-screw extruders.

What effects can be expected from reduction of molding defects?

By reducing plastic molding defects, the defect rate can be improved. even if only a few percent improvement, on an annual basis,Reduction of material loss by millions of unitsIt should never be ignored because it can lead to It is no exaggeration to say that improving the good rate is an immediate profit measure that directly affects operating profit.

There are many different types of molding defects. Let's start by learning about the types of molding defects and considering countermeasures.

Types of molding defects that occur frequently in the field

short shot

Resin does not fill the mold evenly,Partial chipping of molded productsIt is. The main causes are insufficient molding pressure, low resin fluidity, and poor air venting. Short shots are especially likely to occur in complex shapes and thin-walled parts.

Flash (Bali)

Protruded from mold joints, etc.Extra resinof the mold. Insufficient clamping force, mold wear, and excessive injection pressure are the main causes. Regular inspection and maintenance of the mold is essential to prevent flash.

weld line

Formed when resin flows mergeLinear Borderrefers to the "weld line". Insufficient temperature or pressure at flow confluence is the main cause of weld lines. Not only does it cause poor appearance, but it can also lead to reduced strength and cracking of the molded product.

Bubbles (voids)

Inside or on the surface of molded productsHollows and bubblesThis is a molding defect caused by the use of water-containing raw materials, insufficient devolatilization, and excessive injection speed. The use of water-impregnated raw materials, insufficient devolatilization, and excessive injection speed are the main causes. Adequate drying of the raw material and proper degassing design in the extrusion process are required.

Silver streak

Appeared on the surface of the molded productSilver streak marksThis refers to the "I" in the name of the product. The main causes are volatile components, water content, and poor filler dispersion. Pre-drying materials thoroughly and optimizing the kneading process are the keys to preventing silver streaks.

Black spots/foreign matter

For molded productsContains black granular foreign matter or burnt debrisThis phenomenon is caused by carbon residue inside the extruder or in the mold. It is mainly caused by carbon residue generated inside the extruder or mold and foreign matter in the raw material. Improvement can be expected by reviewing the cleaning process and strengthening the filtration process.

Discoloration/yellowing

Whole or part of the molded productColor changeThis is a molding defect that results in Yellowing is particularly noticeable, mainly due to thermal degradation, oxidation, and prolonged resin retention. The risk of discoloration and yellowing can be reduced by designing oxygen blockers and stabilizers.

Warpage/dimension failure

If the molded product isWarping, shrinking, and distorting phenomenaof the product. Uneven cooling, residual stress, and improper gate positioning are the main factors. Optimizing molding conditions and reviewing mold design are keys to maintaining stable dimensions.

Crack/Brittle Destruction

After moldingCracks developedThis term refers to molding defects that are caused by the molding process. It is often caused by material embrittlement, residual stress, or filler agglomeration, and requires special attention when using high-performance materials. It can cause not only appearance defects but also functional defects.

Background of increased defects caused by raw materials

One of the reasons for the increase in defects caused by raw materials,Undispersed additivesare listed below. This leads to localized strength loss and appearance defects.

AnotheFiller agglomeration and volatile gas residueThe risk of defects such as internal bubbles and silver streaks is also increased by Furthermore, for cost reduction purposesRegrind material (recycled material)The increased use of "mixers" is one of the factors causing molding defects. The lack of uniform mixing can lead to a variety of defects.

Measures to control molding defects with twin-screw extruders

By utilizing a twin-screw extruder, molding defects caused by raw materials can be effectively controlled. High shear and high dispersion performance ensures uniform dispersion of additives and fillers in the resin,Prevents uneven color and strength.

In addition, by using a model equipped with a sufficient degassing mechanism, water content and volatile gases can be efficiently removed,Reduces the occurrence of defects such as bubbles (voids) and burnsThe twin-screw extruder can also be used to mix regrind and other recycled materials. In addition, twin-screw extruders can also be used for mixing regrind and other recycled materials.Ensures stable qualityThis allows cost advantages to be extracted without compromising product reliability.

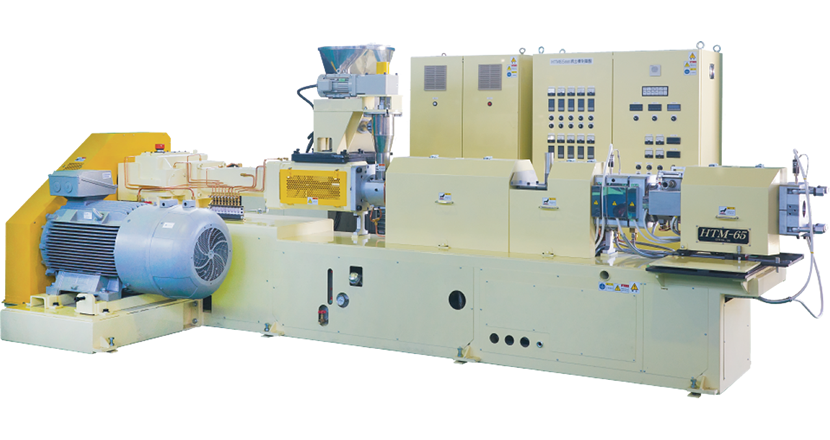

https://cte-japan.com/en/product/htm-twin-screw-extruder/

Equipment that realizes effective countermeasures on multiple fronts against issues such as uneven kneading, gas residue, and resin burning, which are the main causes of molding defects.

Especially in wood powder compounds,Even if pellets are fed directly without pre-drying, stable pelleting is possible while minimizing burns and color irregularities.and can be kept suitable for molding without compromising raw material quality.

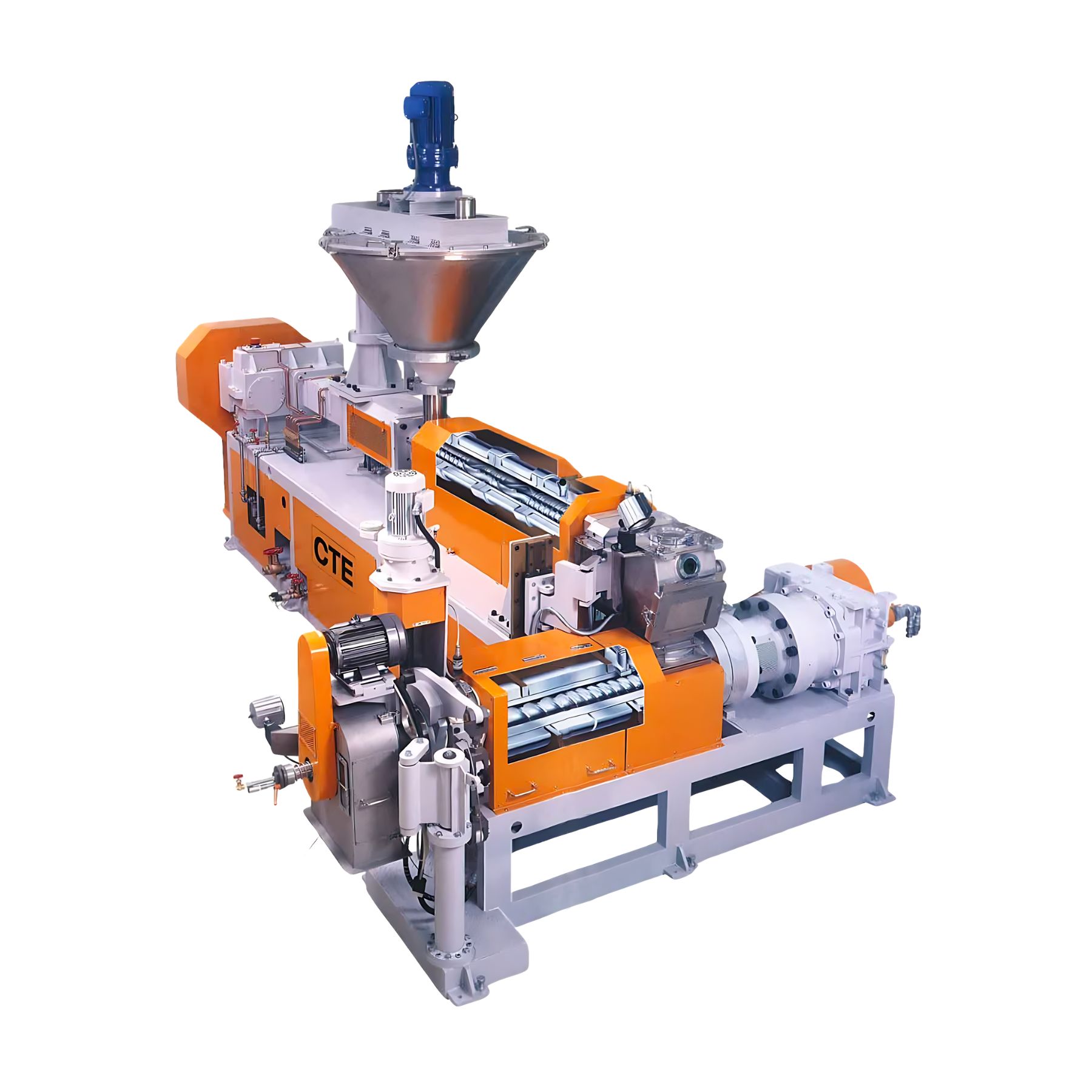

https://cte-japan.com/en/product/htm-tandem-compounding-twin-screw-extruder/

The high kneading structure with multiple high-speed rotors ensures uniform dispersion of fillers and additives, preventing appearance defects due to agglomeration and foreign matter. In addition, the shear time is very short due to the rotor structure, which suppresses unnecessary heat generation and greatly reduces the risk of burning and deterioration of physical properties.

In addition, the non-engaging, interdirectional rotating twin-shaft structure provides excellent outgassing performance, which isDesigned to prevent extrusion failure due to air bubbles in pellets or feed-neck phenomenon (material clogging)It is.

What CTE twin-screw extruders can achieve

CTE's twin-screw extruders achieve high kneadability and dispersibility and excellent outgassing performance due to their interdirectional and non-intermeshing structure.Stable molding of biomass materials and biodegradable resins with minimal burns and degradationis possible.

It also supports the omission of the drying process and low-temperature extrusion, both preventing molding defects and improving productivity.

- Poor dispersion of inorganic filler is an issue.

→Dispersibility is improved,2.5 times the time it takes to change the filter. - Insufficient pre-drying causes quality deterioration.

→ PC (polycarbonate)Pre-drying time can be reduced to 1/3 with no problem.Extrusion could be done.

→ With the installation of vacuum vents.No pre-dryingExtrusion molding is now possible with - Trying to use biomass materials, but the quality deteriorates when blended.

→Biodegradable resins such as PLA and PBAT mixed with fillerExtrusion without quality deterioration

→directional marker or indicatorBiomass materials such as wood flour and starchand resin can be extruded without burning the material.

Data showing performance of CTE products

MFR comparison of biodegradable resin compounds

Prevents degradation by suppressing MFR increase even with high throughput

| (data) item | unit | CTE HTM Tandem Extruder (Non-intermeshing, interdirectional rotation) |

Tandem extruders from other manufacturers (Engagement and co-directional rotation) |

|---|---|---|---|

| Screw diameter | mm | 50 | 46 |

| throughput | kg/h | 200 | 50-130 |

| Screw rotation speed | rpm | 280 | 120-180 |

| Extrusion grade | g/10min | 0.6 | 3.3 |

| Injection grade | g/10min | 25 | 39 |

PBAT:CaCO3=53:47 (extrusion grade). PBAT:CaCO3=75:25 (injection grade)

In compounds of biodegradable resin and CaCO₃, the CTE HTM tandem extruder maintains lower MFR values than conventional machines. This means that despite the high throughput, the extruder is able to extrude without degrading the material,Reduce the risk of defects such as reduced physical properties and dimensional variation during moldingThis is the basis on which it is possible to

Comparison of throughput

Stable molding even with high filler content

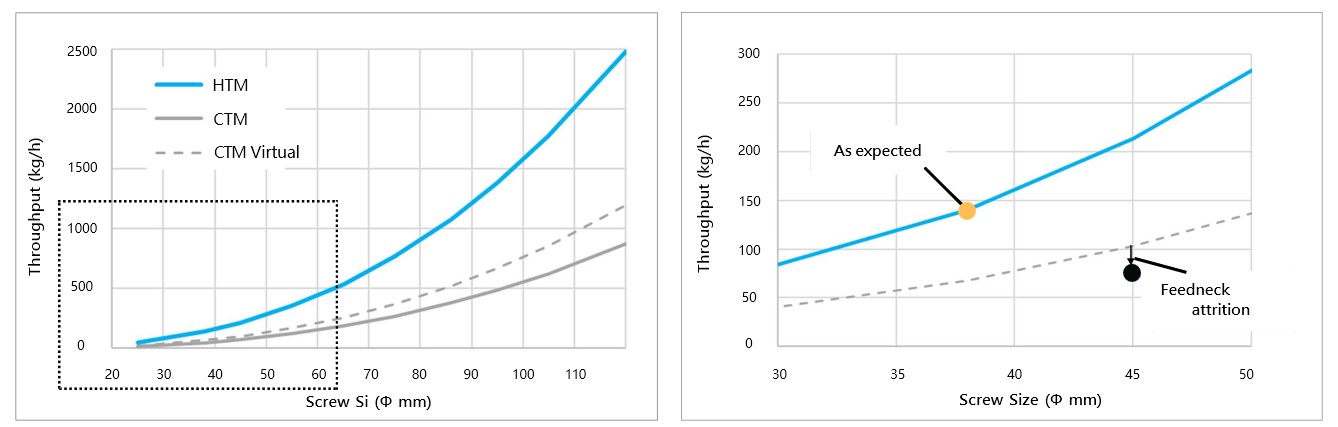

The graph below compares the throughput for each screw diameter between HTM (non-engaged dissimilar direction) and CTM (engaged same direction).

CTE's HTM extruder (blue line) achieves higher throughput in the same size compared to the conventional CTM (gray and dotted lines) with the same direction and intermeshing structure. In particular, the enlarged image on the right side shows that the HTM machine maintains stable throughput due to smooth material feeding, whereas the CTM machine suffers from a feed-neck phenomenon.

This result is also true for high filler formulations.Prevents material clogging and air bubbles, and suppresses molding defects.This is a major strength of the HTM extruder.

Molding defects are caused not only by molding conditions, but also by insufficient kneading and degassing of raw materials and poor temperature control. Defects caused by materials such as undispersed additives, agglomeration of fillers, and residual water-containing gas are important to what extent they can be carefully treated in the previous process.

CTE's twin-screw extruders combine high kneadability and dispersibility with excellent degassing performance due to their non-intermeshing, interdirectional rotating structure. Even with high filler materials such as wood powder and CaCO₃,Stable extrusion while preventing burns and jamsThe risk of molding defects such as air bubbles and dimensional irregularities can be fundamentally reduced with