Bioplastic production

Bioplastics are traded in the price range of 300 to 600 yen per kilogram, more than twice the price of petroleum-derived resins. Demand for bioplastics is growing amid the need for environmental friendliness, and if companies can establish their own processing systems, they will have an expanding business opportunity with the potential for high profits. The twin-screw extruder, which excels in kneading and dispersion, is attracting attention as a manufacturing facility that supports the realization of this goal.

Growth and Business Opportunities in the Bioplastics Market

Rapidly growing Southeast Asian markets

The bioplastics market in Southeast Asia is,Continues to grow at over 10% per year and will expand at 16-17% per year through 2030predicted that*Thailand is also a major producer of PLA (polylactic acid) and PBS (polybutylene succinate). In particular, Thailand is strengthening its international presence as a production base for PLA (polylactic acid) and PBS (polybutylene succinate), and is one of the world's major producers.

Expanding Applications and the Rise of New Materials

In addition to PLA, our mainstay product, new biodegradable resins such as PBS and PHA are being utilized,Diversified applications from food packaging to agricultural, medical, and automotive parts.

Among them, PHA is a next-generation material with marine degradability and is beginning to be produced commercially. These biodegradable resins account for more than 60% of all bioplastics, and*The market is expanding further.

Competitive advantage as a supply base

Southeast Asia, with its abundant agricultural resources, low-cost human resources, and government support, has great potential as a future global supply base, and foreign manufacturers are investing in the region in rapid succession. The global supply of bioplastics, centered on Asia, is expected to grow toProjected to nearly triple in the next five years*The time to enter the market is now, as there are also

Product Development and Business Models Expanded by Bioplastics

From daily necessities to industrial applications

Bioplastics were originally used mainly in the daily necessities field, such as plastic bags, straws, and cutlery, but in recent years, their application areas have been expanding.

In addition to light packaging applications such as wrapping materials and films,Automobile parts, medical equipment, agricultural materialsand other industrial applications, and it is becoming possible to commercialize products with features such as durability and heat resistance.

Diverse development forms

As these material characteristics evolve, business models are also diversifying. As a factory-based business without a specific brand, the OEM (contract manufacturing) supply model is effective.

In addition, for companies that have products developed in-house, the development of these products as private brands (PB) will enable them to appeal directly to the market. In addition, in cooperation with local governments and distribution companiesResponding to de-platforming measuresCollaboration with government agencies and trading companies to develop products that address social issues will also expand, such as

Thus, a rare balance of environmental value and economic efficiency exists in the business of bioplastics. Since contribution to the global environment is directly a differentiating factor for companies, it is becoming increasingly attractive as a new source of revenue in this era of sustainability.

Market Trends|Investment in manufacturing facilities attracting attention

As the demand for bioplastics increases, it is becoming increasingly significant to establish an in-house manufacturing system. While reducing the cost of raw material procurement, it is easier to secure a competitive advantage through differentiation, as it allows for flexible product design according to application and function.

Contract manufacturing needs from resin product manufacturers and trading companies are also on the rise.and with its own facilities, the company is well positioned to respond to external manufacturing requests.

Furthermore, the market for bioplastics as an environmentally friendly material is expanding along with the growing international trend toward sustainability. Compared to conventional petroleum-derived resins, the technological barriers to entry are relatively low,There is plenty of room for entry, even for latecomers.This makes it an attractive option for companies looking to launch new businesses.

Technical challenges in bioplastic production

While bioplastics can reduce environmental impact, they present several technical challenges in terms of processing.

For example, some materials lack thermal stability and may decompose during heat treatment. Also, the risk of degradation due to moisture absorption cannot be ignored. In addition, flexibility and heat resistance must be adjusted with additives according to the required physical properties, which requires precision in mixing and kneading techniques. There are also variations among raw materials,Manufacturing facilities capable of high dispersion performanceis required.

Main coping strategies and approaches to processing issues

The challenges in processing bioplastics are many and varied, and suitable solutions vary depending on their properties and applications. For example, the following technical approaches are used to prevent thermal degradation

- Adoption of special molding machines that enable processing at low temperatures

→ Compatible with heat-sensitive bio-materials, but applications are easily limited. - Thorough pre-treatment with dryers and dehumidifiers

→Risk of deterioration due to moisture absorption is reduced, but facilities are dispersed and management becomes more complicated. - Pre-mixing in premix equipment

→ Although the kneading load can be reduced, the process changes for each material, making operations more complex.

While these individualized responses are effective to a certain extent, there are only a limited number of devices that can address multiple issues all at once, and the challenge of stabilizing and streamlining production still remains. Against this background,There is a growing need for equipment that can handle complex processes such as kneading, dispersion, and devolatilization in a single unit.The "twin-screw extruder," which we will introduce next, has been attracting attention.

Twin-screw extruder for strong kneading and dispersion

For the complex technical challenges of bioplastic production, a twin-screw extruder can meet multiple challenges with a single machine. Below we describe the features and benefits of twin-screw extruders.

Uniform kneading and dispersion ensure freedom in adjusting physical properties

The twin-screw extruder has two intersecting screws that rotate,Homogeneous mixingThe product can be used in a wide range of applications. Physical properties such as heat resistance, flexibility, and transparency can be adjusted with high precision according to the application.

We provide high performance in materials such as bioplastics, which vary in composition ratio and functionality from product to product.

Devolatilizing function expels moisture and gases, contributing to quality stability

Some materials are prone to thermal decomposition when they absorb moisture. The twin-screw extruder is equipped with a devolatilization zone,Efficiently removes excess moisture and volatile components generated during heatingsuch as high filler compounds.

It reduces the risk of material deterioration and contributes to processing stability and product quality retention.

Flexible production support from prototyping to mass production

By adjusting the screw configuration and barrel length,Smooth scale-up from small-lot prototype development to medium-volume and high-volume productionThe following is a list of the most common ways to do this.

It can be used as an infrastructure to accelerate business speed by reducing lead time from the development stage to market launch and by flexibly responding to product lineup expansion.

Processes multiple processes on a single machine, integrating and streamlining the manufacturing process

Conventional dispersed processes such as drying, mixing, and devolatilization can be handled in a single process.This makes it efficient in terms of capital investment and operation. The twin-screw extruder is positioned as the core equipment for bioplastic production because of its ability to achieve both stable quality and high productivity while reducing personnel load and the number of processes.

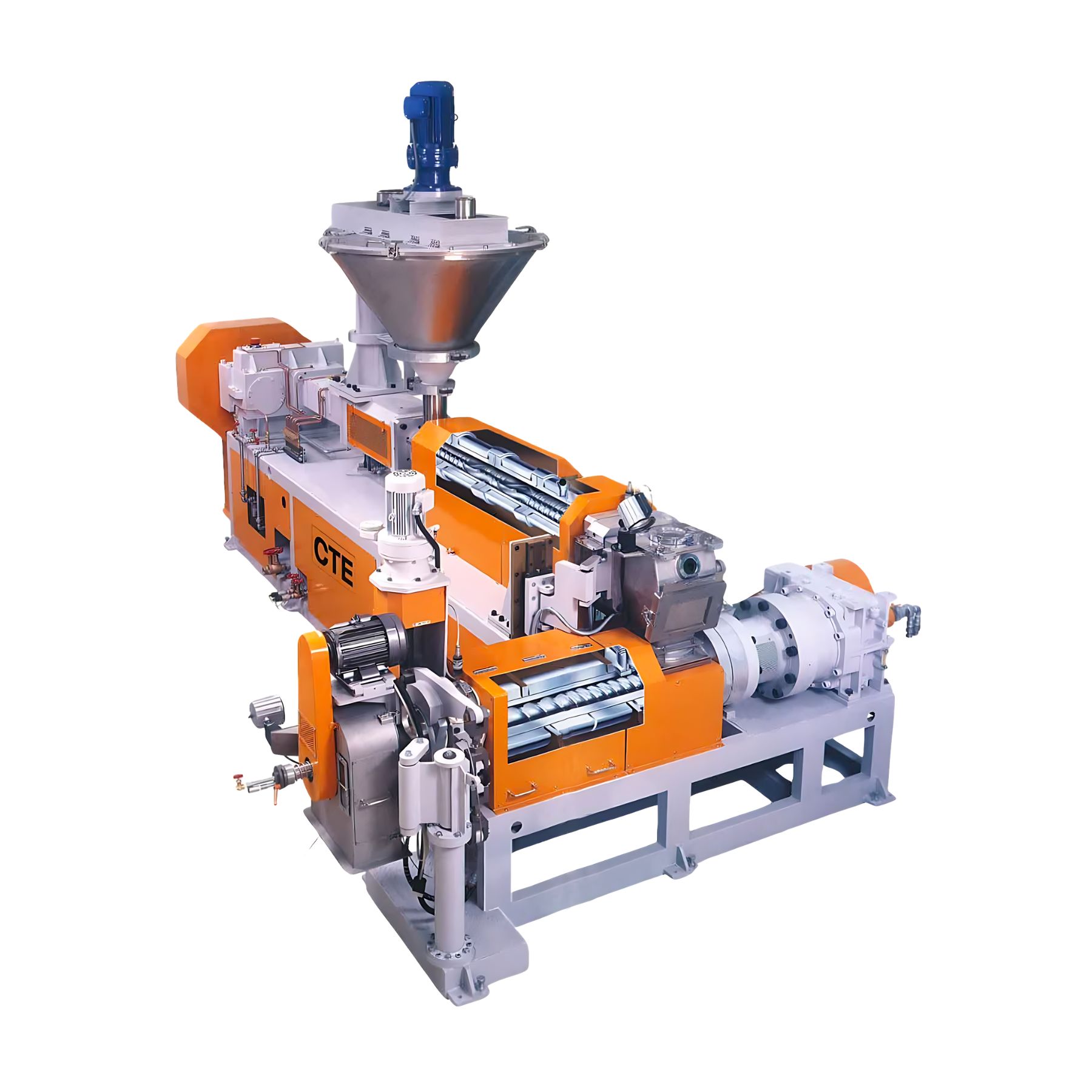

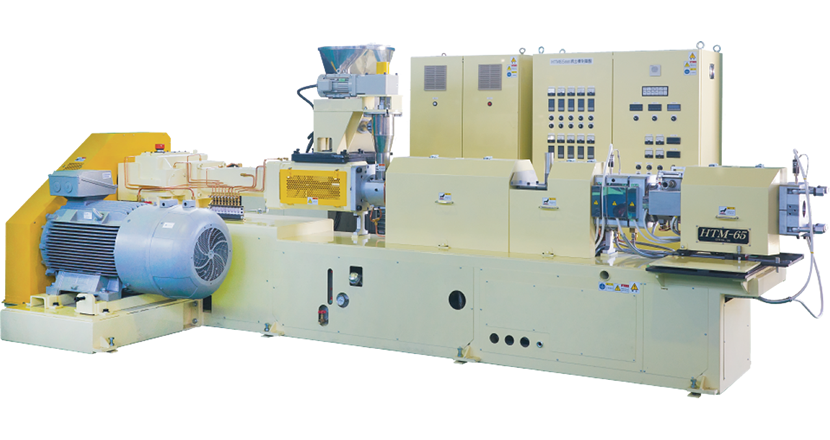

One of CTE's twin-screw extruders, the HTM tandem kneading extruder,High density fillers, recycled materials and biodegradable resinsThis extruder can be used for a wide range of plastic processing applications, such as It can also handle high filler content of inorganic fillers such as talc, calcium carbonate, and titanium dioxide, and is capable of processing heat- and shear-sensitive resins such as rigid PVC, recycled PVC, and PBAT with minimal degradation and high-quality finishing.

Furthermore, due to the unique structure of non-engagement and inter-directional rotation,High outgassing performance prevents bubbles and molding defects in pelletsIt is suitable for use in the chemical/material recycling field. It also has excellent kneadability and dispersibility, making it suitable for use in the chemical and material recycling fields.

The screw configuration is segmented and can be flexibly customized according to material characteristics and purpose. From plastic raw materials to recycled materials and biomass resins,Versatility and productivity for a variety of recipesThis is an extremely effective solution for the plastics business from the

summary

As one of the few material businesses that can achieve both environmental value and profitability, bioplastic production is a field that will attract increasing attention in the future. Among these, the twin-screw extruder, which plays a central role in the production process, is capable of stabilizing quality through its high mixing, dispersing, and devolatilizing capabilities,Can increase competitive advantage in terms of both differentiation and efficiencyis the appeal of this product.

As product diversification and market needs continue to expand, bioplastic production is an area that should be considered right now as a new business axis for vertical integration, where the company is involved in the entire process from raw materials to finished products.