What is an oriented-rotary twin-screw extruder?

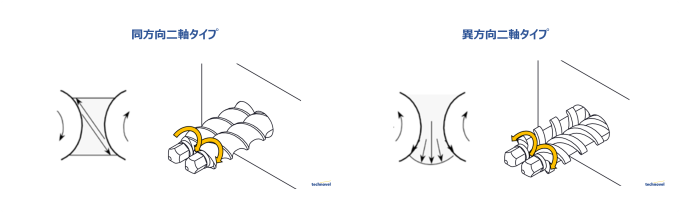

Twin-screw extruders can be broadly divided into two types based on the direction of screw rotation: co-rotating twin-screw extruders and heterotaxial-rotating twin-screw extruders. Here, we summarize the features, applications, and technical merits of the co-rotating twin-screw extruder. If you are considering the introduction of a twin-screw extruder, please refer to this section.

What is an anisotropic twin-screw extruder?

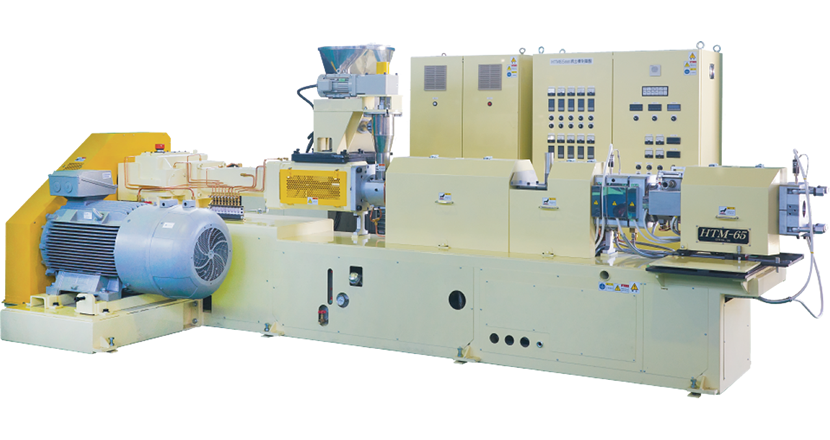

Counter Rotating Twin Screw Extruder is a twin screw extruder with two screws that rotate in opposite directions.Structure that rotates in the opposite directionThis is an extruder with a It is suitable for processing heat-sensitive materials and materials that require high pressure stability and gentle kneading. It is especially suitable for PVC with poor heat stability and materials that require less fiber damage, such as natural fiber composite materials such as wood powder. It is also used in fields that require the maintenance of physical properties, such as medical and food packaging materials.

Features of Structure and Rotation Method

https://www.technovel.co.jp/2490/

In an unidirectional twin-screw extruder, the left-hand screw rotates clockwise (CW) and the right-hand screw rotates counterclockwise (CCW). This counter-rotation causes the material to be sandwiched between the screws and transported forward,Gentle and stable processingIt is Shear force is lower than that of a co-rotating twin-screw extruder, and shear heat can be suppressed to enable processing at lower temperatures.

Comparison with other methods (difference from co-rotating)

| Heterodirectional rotary type (Counter) | Co-rotating | |

|---|---|---|

| shear force | small | big |

| mixing power | gentle | strong |

| thermogenesis | few | numerous |

| Suitable materials | Heat-sensitive resins (PVC, etc.) | Functional additives and complex formulations |

| Self-cleaning | Low to medium | high |

| carrying power | Stable, pressure-feeding type | kneading element |

Main applications and processing examples

Extrusion of thermoplastic resin

Thermoplastics are resins that soften when heated and harden when cooled. Among them,Hard PVC and soft PVC It is widely used in pipe and building material forming using It is also suitable for use in profile molding, door frames, and conduit pipe mass production lines.

Natural fiber composite materials (WPC, etc.)

Suitable for processing WPC products that require mixing natural materials such as wood flour and hemp fiber with resin at low temperatures. Reduces excessive shearing by the screw,Uniform dispersion without breaking fibersThis allows molding without loss of strength or appearance.

Materials for medical and food packaging

Resins for medical and food packaging areHeat sensitive and easily degradedTherefore, an unidirectional rotary twin-screw extruder with stable torque and low-temperature processing capability is effective. This can achieve stable processing, especially in products where quality maintenance is required.

Technical Advantages

Good stability at high torque and pressure

The unidirectional rotary twin-screw extruder can stably feed material at a constant pressure while suppressing pressure fluctuations during extrusion through "positive displacement conveying," which pushes the material between the screws. This allows,Reduces variation in molding qualityThe point is a major advantage.

Low shear and low temperature processing

Shear stress can be suppressed by counter-rotating two screws. Heat generation during shearing is also suppressed,Easy to maintain physical properties even with materials at high risk of thermal degradationThe molding process is stable, and the material can be molded stably. It is particularly well suited for materials with poor thermal stability.

Strong for conveying powder materials

by two screws rotating in opposite directions,Conveying materials while pulling them inThe process is capable of stably supplying powders and resins with slippery properties. It is also effective for processing specially formulated base materials and can be expected to improve yields.

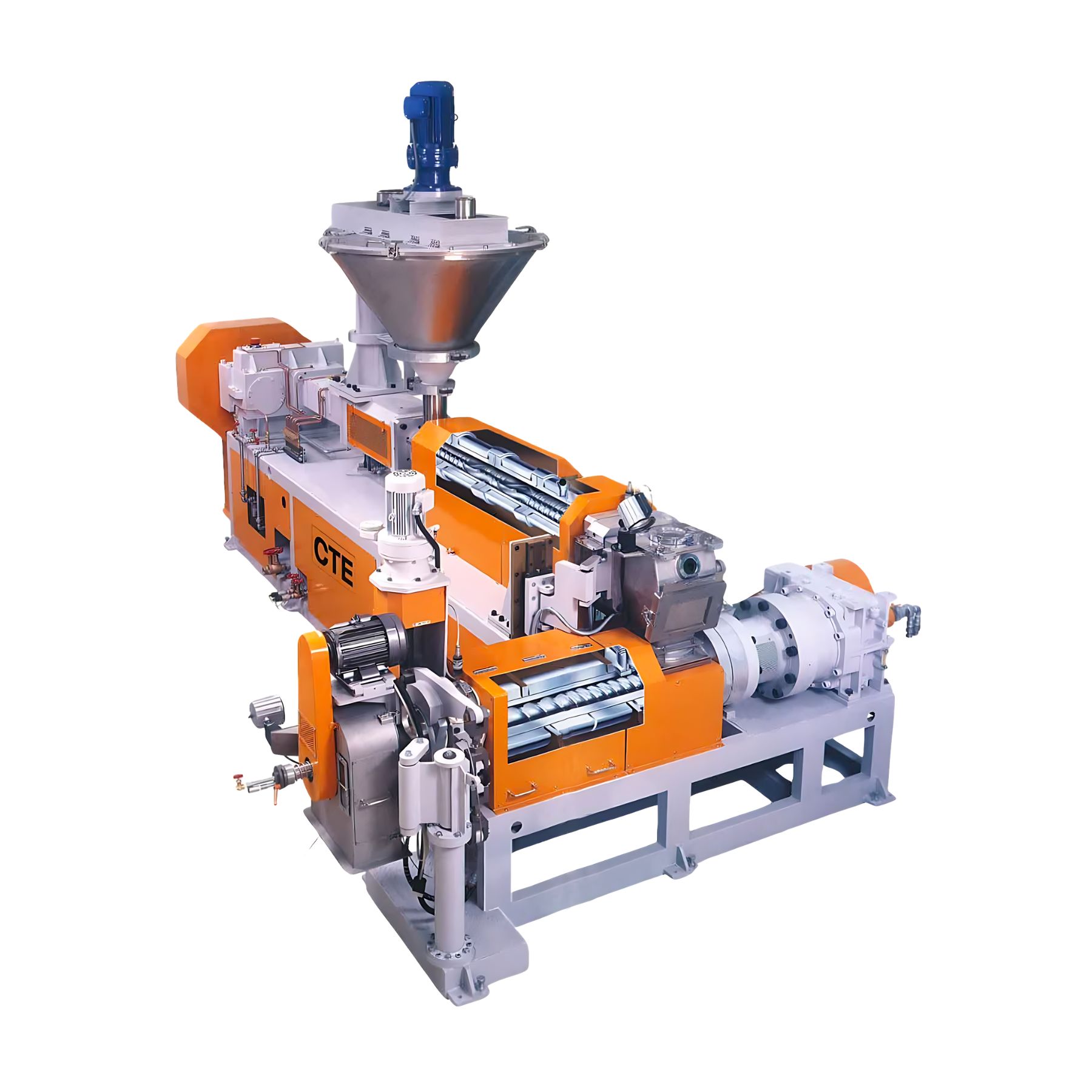

CTE's twin-screw extruders combine high mixing, dispersing, and degassing performance,Compatible with complex compounded materials, recycled materials, and high filler compoundsThe flexibility of this product is its ability to be used in a wide range of applications. It is suitable for sites where both quality and productivity are required, as it ensures stable physical properties while minimizing burns and agglomerations.

It also contributes to the reduction of material loss and review of raw material costs, and improves the profit structure of the entire production line. When considering the introduction of a twin-screw extruder, please consider CTE, which is backed by our proven track record and technical capabilities.

Summary: Cases in which you should choose an oriented-rotary twin-screw extruder

The unidirectional rotary twin-screw extruder is suitable for processing heat-sensitive materials such as PVC and additive resins because of its ability to process at low temperatures and low shear. The structure that allows uniform kneading with minimal fiber breakage is effective for processing natural fiber composite resins such as wood flour and hemp fiber.

In addition, high pressure stability due to positive pressure transfer between screws contributes to continuous forming of profiles and tubes. The flow velocity distribution is clear and controllable, making it suitable for products that require quality reproducibility.