Reduce Quality Complaints and Waste Costs with Resin Degradation Prevention

Resin degradation is the root cause of quality complaints. Since it is directly related to trust in the material and the company, a single claim can result in the loss of profits and customers.

From the perspective of generating trust and profit by protecting materials, this article will summarize the causes of deterioration and management risks, and provide details on effective process management and the use of twin-screw extruders as improvement measures.

Resin degradation is a hotbed of quality complaints

Even a single quality complaint for plastic products can cause tremendous losses to a company. The loss of customer trust and profits is immeasurable, and sometimes even market share can be affected.

Especially defects that appear on the surface of plastic products,Invisible deterioration of the material itselfTherefore, it is necessary to take preventive measures to prevent deterioration from the raw material stage. This will greatly reduce product defect rates and improve yields.

Factors and effects of resin degradation

Common Deterioration Mechanisms

One of the main mechanisms of resin degradation is the reheating ofMolecular Chain RuptureIt is. Heating, especially at high temperatures for long periods of time, causes the molecular chains to break up, resulting in a resin that is less strong and more brittle.

AnotheWater content and oxidation of raw materialsThe appearance and hygiene of the product can also be compromised by problems such as discoloration of the resin, odor, and bubbles, depending on the Other,Excessive heat shearis another factor in resin degradation. Thermal degradation can cause problems such as gas generation and carbon deposits.

Impact on Management Risk

What are the risks to business operations that can result from neglecting resin deterioration? The first risk is the cost of dealing with complaints, delays in delivery, and an increase in lost products. These negative effects on management are inevitable.

Further,Risk of litigation or recall if seriousOnce a customer trust relationship is lost, it is not easy to recover it, and the result can be a long-term loss of revenue. Once trust with customers is lost, it is not easy to regain it, and as a result, it may cause a long-term decline in profits, so early action is required.

How to Prevent Resin Deterioration? Introducing a basic approach

Heating Management

To avoid unnecessary heat history,Optimization of temperature profiles and control of reheatingis essential. By optimizing the heating conditions, the destruction of the molecular structure can be prevented and the original performance of the resin can be maintained.

Moisture and oxygen management

To prevent resin degradation, it is also important to control moisture and oxygen in raw materials.Pre-drying and nitrogen purgingThoroughly enforcing the following measures prevents deterioration due to oxidation and hydrolysis, and prevents deterioration in the appearance and physical properties of the product.

Utilization of stabilizers

Proper use of additives such as antioxidants, heat stabilizers, and UV absorbers protects the molecular structure of the resin and minimizes degradation.Selection of stabilizers according to applicationis the point.

process optimization

Prevents excessive shearing and retention and suppresses bubble generationKneading and devolatilization designis required. Optimizing the entire process will enable consistent product quality and increased productivity.

Deterioration control realized by twin-screw extruder

The twin-screw extruder has been attracting attention as a device that can optimize the process for resin degradation countermeasures. The devolatilization mechanism eliminates theEffective removal of volatile componentswill be.

AnotheDesigned to avoid overheating and overshearingAnother major advantage is that the molecular structure can be protected with

In addition, anti-degradation agents and various stabilizers areUniform kneadingThis directly leads to longer product life. Twin-screw extruders are indispensable in preventing product problems and ensuring stable quality.

https://cte-japan.com/en/product/htm-twin-screw-extruder/

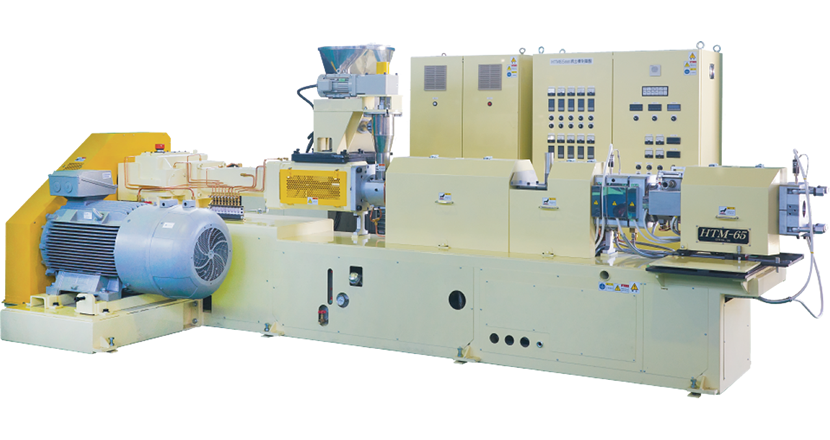

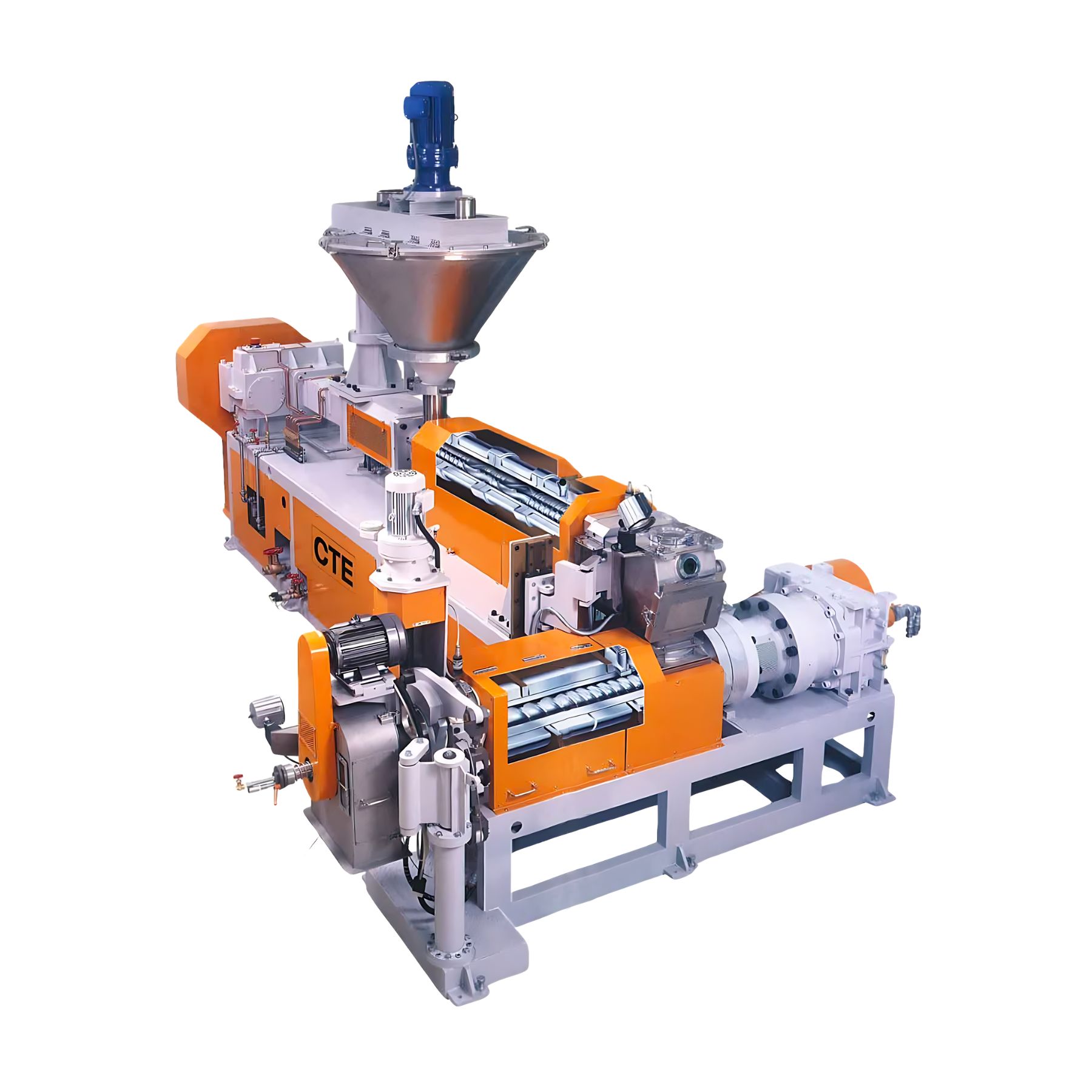

The HTM twin-screw extruder has an intermeshing twin-screw structure with interdirectional rotation,High kneadability and excellent outgassing performanceThe machine achieves the following. The high-speed rotor of the Banbury mixer type provides high shear to the resin, while repeated compression and release reduces heat generation, enabling low-temperature extrusion.

It ensures uniform dispersion while preventing resin degradation and prevents the inclusion of air bubbles that can cause molding defects. This extruder is also suitable for processing high density filler and recycled materials, and has the ability to handle a wide range of materials.

https://cte-japan.com/en/product/htm-tandem-compounding-twin-screw-extruder/

The HTM tandem extruder is based on the technology of the HTM twin-screw extruder and combines a twin-screw kneader and a large diameter single-screw extruder.High kneadability and outgassing performanceand in the single-axis extrusion sectionLow temperature, low speedExtrusion is possible with

It can process compounds with high filler concentration, recycled materials, and biodegradable resins in a stable manner while minimizing burnout and degradation. In addition, the segmentation of the screw allows for flexible handling of a wide variety of materials.

What CTE twin-screw extruders can achieve

CTE's twin-screw extruders are capable of meeting material and molding challenges that were difficult to meet with conventional equipment, thanks to our reliable technology.Sensitive materials such as recycled materials with thermal history and biodegradable resinsBut it can be extruded without loss of physical properties.

Further,Drying process can be omitted or shortened.This will also contribute to increased productivity.

- Degradation of physical properties is noticeable in materials with thermal history, such as recycled materials.

→Repellet of recycled material, compared to engaged co-directional biaxialDeterioration was minimized and controlled. - Insufficient pre-drying causes quality deterioration.

→ PC (polycarbonate)Pre-drying time can be reduced to 1/3 with no problem.Extrusion could be done.

→ With the installation of vacuum vents.No pre-dryingExtrusion molding is now possible with - Trying to use biomass materials, but the quality deteriorates when blended.

→Biodegradable resins such as PLA and PBAT mixed with fillerExtrusion without quality deterioration

→directional marker or indicatorBiomass materials such as wood flour and starchand resin can be extruded without burning the material.

Data showing performance of CTE products

MFR comparison of biodegradable resin compounds

Prevents degradation by suppressing MFR increase even with high throughput

| (data) item | unit | CTE HTM Tandem Extruder (Non-intermeshing, interdirectional rotation) |

Tandem extruders from other manufacturers (Engagement and co-directional rotation) |

|---|---|---|---|

| Screw diameter | mm | 50 | 46 |

| throughput | kg/h | 200 | 50-130 |

| Screw rotation speed | rpm | 280 | 120-180 |

| Extrusion grade | g/10min | 0.6 | 3.3 |

| Injection grade | g/10min | 25 | 39 |

PBAT:CaCO3=53:47 (extrusion grade). PBAT:CaCO3=75:25 (injection grade)

In the blending of biodegradable resin (PBAT) with CaCO₃, CTE's twin-screw extruder showed an MFR of only 0.6 g/10 min after extrusion, even when operated at high throughput (200 kg/h) and high speed (280 rpm).

The CTE machine shows a small decrease in molecular weight, confirming that degradation is suppressed.Does not compromise the physical properties of biodegradable resins and does not reduce productivityThe performance is suitable for processing sites.

Comparison of die tip resin temperature

Small deviation between set temperature and actual temperature, suppressing thermal degradation

| (data) item | unit | CTE HTM Tandem Extruder | Conventional twin-screw extruder |

|---|---|---|---|

| throughput | kg/h | 100 | 50 |

| Screw rotation speed | rpm | 140 | 500 |

| Die tip resin temperature ratio | SV | 180 | 180 |

| Resin temperature | ℃ | 180 | 204 |

In the HTM tandem extruder, when the die temperature is set at 180°C, the actual resin temperature is also stable in the 180°C range,Unnecessary temperature increase is not occurring.

In general, when resin is heated above the set temperature, thermal degradation such as molecular chain scission and yellowing is likely to occur. A small discrepancy between the set temperature and actual temperature indicates an extrusion environment that can maintain stable quality.

How to control resin degradation and maintain stable quality is an important theme that relates not only to product reliability but also to the company's continued growth. In recent years, in particular, there has been an increase in difficult-to-handle materials such as recycled materials and biodegradable resins, and the selection of equipment that can accurately process these materials is required.

CTE twin-screw extruders are,Designed for stable extrusion without compromising material characteristicsis applied. If you are interested in preventing quality problems or improving productivity, please contact us through the official CTE website.