How to reduce the cost of plastic processed products

Soaring crude oil prices and other factors have prompted manufacturing sites to review their costs. Plastic processing is no exception to this response. Here, we will discuss cost issues in plastics processing and how to reduce costs using twin-screw extruders.

Organize cost increase factors

Four factors that contribute to higher costs in plastics processing are

Material loss

Defective products and offcuts generated in the manufacturing process are a cost factor that cannot be ignored. A low yield not just increases material costs,but also raises processing and disposalexpenses.

Difficulty in handling recycled materials

The significant quality and lot-to-lot variability of recycled materialsmake them difficult to use in stable manufacturing.As a result, processing losses increase, and the cost-saving benefits of using these materials cannot be fully realized.

Power Cost

Due to the recent rise in the unit price of electricity,Energy costs for processes are increasing.This drives up the cost of production, which is a key factor in the cost of goods sold. Inefficient manufacturing processes, in particular, can have a significant impact on these overall costs.

Outsourcing processing cost

Outsourcing the kneading of additives and fillers increasesprocessing and logistics expenses, which drives up the final product cost.Additionally, the long lead times involved create a significant challenge for production management.

Cost reduction methods that can be considered

There are a wide variety of means to reduce costs in plastics processing. Below are some of the typical innovations practiced in the field.

Optimization of manufacturing conditions

Reviewing processing conditions—such as temperature, pressure, and rotation speed—makes it possible to reduce both the defect rate and energy consumption.In particular, carefully managing settings according to the characteristics of each resin minimizes material loss and the need for reprocessing.

Review of material selection

Through strategic material selection—such as choosing a resin grade with high workability and recycled materials with excellent stability—it is possible to reduce manufacturing problems and molding defects.Furthermore, costs can be lowered while maintaining performance by carefully adjusting the type and mixing ratio of additives and fillers.

Enhanced mold maintenance

Since the wear and contamination of molds often lead to quality problems,regular maintenance is essential for preventing molding defects.This practice, in turn, reduces unnecessary disposal and reprocessing of materials.

Optimize inventory management

Properly managing inventory in accordance with the production schedulereduces material waste and improves cash flow, mitigating the high storage costs and disposal risks associated with excess inventory.

While these efforts can achieve some cost reductions,more significant and structural improvements require facility upgrades. One key upgrade attracting attention is the introduction of a twin-screw extruder.

Twin Screw Extruder Enables Structural Cost Reduction

What Makes Twin-Screw Extruders So Effective?

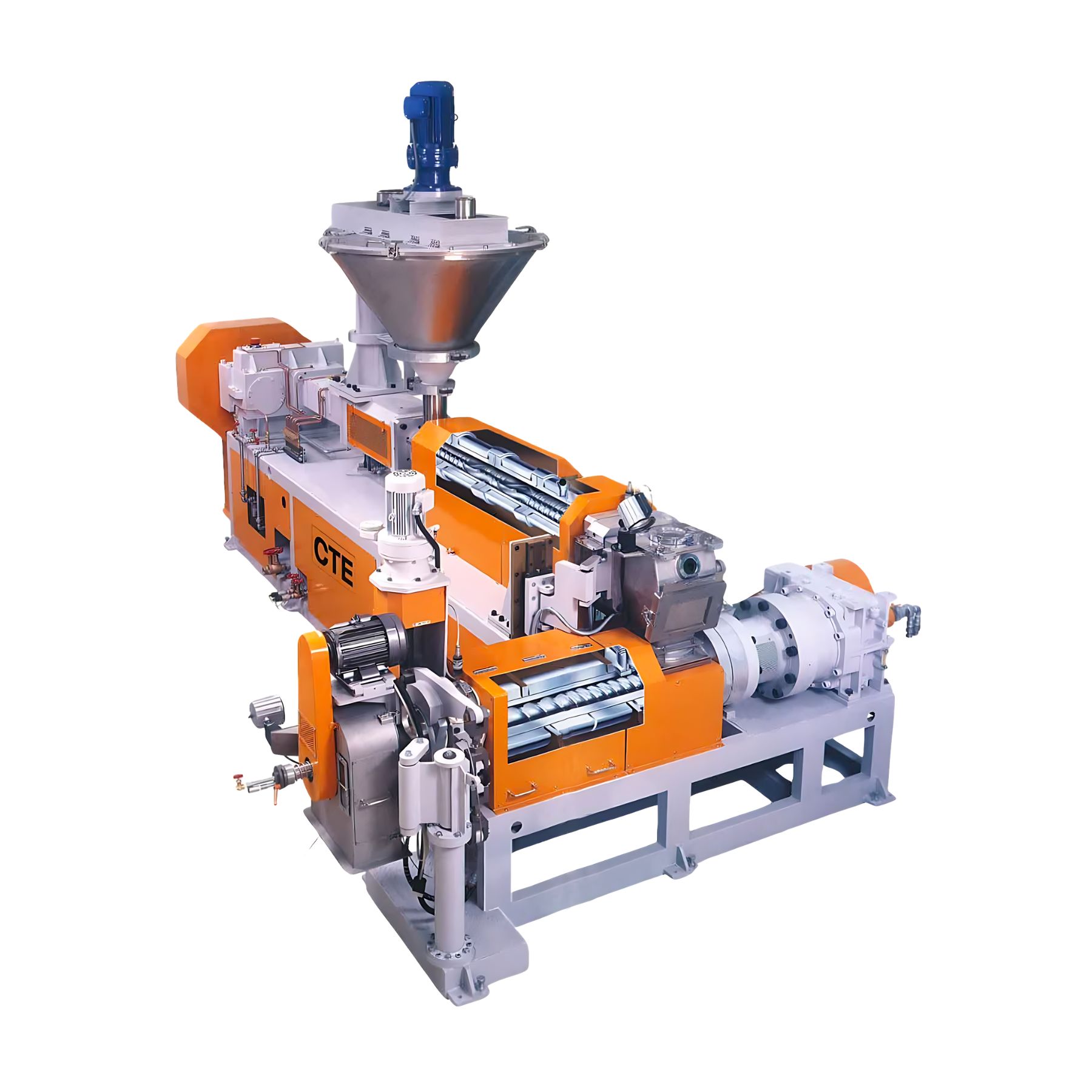

A twin-screw extruder is a device that continuously produces homogeneous pellets by heating and kneading raw materials. Due to their high productivity, they are widely used across the plastics processing industry. A primary advantage of twin-screw extruders is their excellent kneading and dispersion capability, whichenables even dispersion of additives and fillers.This makes them particularly effective for creating high-quality compounds from a mixture of different raw materials.

Another key feature is their high degassing performance. This function removes trapped gases during the process, which prevents defects and significantly improves the quality of the final product. Overall, the ability to streamline production while ensuring consistent quality makes the twin-screw extruder a highly valuable asset.

The introduction of a twin-screw extruder can structurally reduce the following costs in plastics processing:

Reducing costs by prompting the use of recycled materials.

Thanks to its superior mixing and dispersing performance, a twin-screw extruder can homogeneously process even inconsistent recycled materials.This capability reduces dependence on virgin materials, which helps stabilize raw material costs, promoting more efficient use of resources.

Reduces outsourcing costs by in-house production.

A twin-screw extruder allows you to efficiently knead additives and fillers in-house, which reduces manufacturing costs by eliminating outsourcing and transportation expenses.This also provides the flexibility to make on-demand adjustments to production quantities,minimizing the risk of excess inventory and improving overall cost efficiency.

Material loss rate can be reduced

By integrating the entire workflow—from raw material feeding to kneading and pelletizing—the twin-screw extruder minimizes material loss between production stages. This streamlined processsignificantly increases the yield rate and ensures stable quality,leading to more efficient production overall.

The equipment must deliver high kneading power and controllability to handle difficult-to-process materials such as recycled materials and biomass, while maintaining a strong cost advantage.

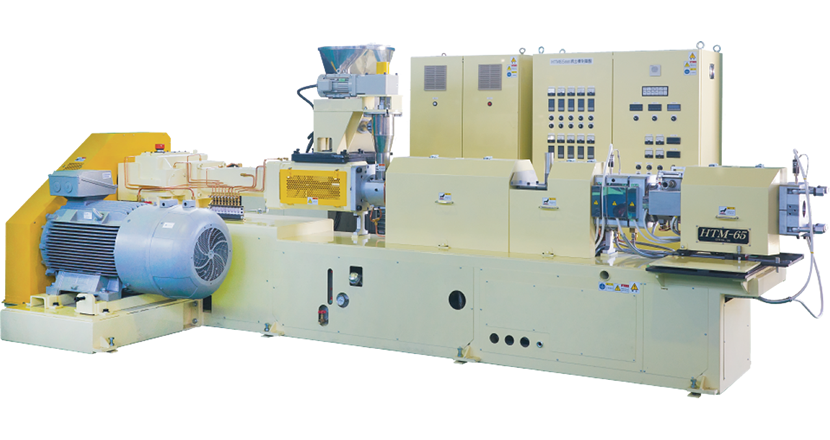

The HTM type tandem kneading extruder features a Banbury mixer type rotor with a twin-shaft structure utilizing non-intermeshing, interdirectional rotation.It is designed for uniform kneading while applying strong shear to the resin.Furthermore, the large-diameter single-axis extrusion section enables forming at low temperatures and low speeds, therebyreducing material burns and deterioration and enabling stable handling of difficult processingsuch as high filler compounds.

High degassing performanceprevents defect factors such as air bubbles and feed necks,improving yield rate and reducing processing loss. This extruder achieves both stable product quality and cost reduction simultaneously.

summary

The introduction of twin-screw extruders has the potential to go beyond mere cost reduction and transform management strategy itself by enabling a fundamental review of raw material strategies. By promoting the efficient use of recycled materials and expanding in-house production capabilities,raw material costs and outsourcing costs can be significantly reduced.

Furthermore, the reduction of material losses improves yield rates and increases productivity. These structural cost reductions contribute to establishing a sustainable production system and represent a major step toward enhancing the company's competitiveness.