Businesses that can be done with plastics processing

For those interested in businesses related to plastics processing, this article summarizes business models that are easy for even beginners to enter and the equipment needed to perform processing. We also explain the equipment suitable for differentiation from other companies, so please refer to this article.

Profitable business model

Sales of recycled plastic pellets

This is a recycling business that crushes, heats, and kneads waste plastic to make re-pellets. As awareness of environmental issues grows worldwide, businesses that recycle waste plastics have been in the limelight in recent years. Among them is the sale of recycled plastic pellets by utilizing local industrial waste and other materials,Reduced procurement costs to ensure profits.is the appeal of this product.

In particular, when the price of crude oil rises, the price of virgin materials also rises in tandem, and pellets made from recycled plastic are expected to be in high demand.

Contract manufacturing of small-lot custom-made products

Contract manufacturing of plastics is the business of compounding and kneading according to the requirements of each customer. While many companies only handle mass production, being able to handle small-lot custom-made products is,It also differentiates us from other companies..

Furthermore, by utilizing a twin-screw extruder, it is possible to use the flexibility of mixing as an advantage. Another advantage of the twin-screw extruder is that it makes it easy to start a business on a small scale, without the need for large-scale facilities.

High-performance masterbatch production

Masterbatch manufacturing is the production of pigments and additives kneaded into base resins to add value to plastics. Pigments and additives are uniformly kneaded into the resin using a twin-screw extruder to provide products with a variety of highly functional properties such as antibacterial, flame retardant, and antistatic.

If we can provide a stable supply of high-function plastic products, it can become a highly profitable business with a view to developing our own brand. This is because the market demands technology and quality,This is an area where even small and medium-sized companies can compete.

Production and sales of bioplastics

In recent years, the bioplastic market using biomass-derived or biodegradable resins has been expanding globally in order to realize a sustainable society. In particular, materials such as PBAT, PLA, and PBS are attracting attention as alternatives to conventional petroleum-based plastics,Diverse applications such as food containers, packaging materials, and agricultural filmsThe adoption of this technology is progressing in the

In this field,Accuracy of temperature control and kneading control during processing is importantTherefore, the selection of appropriate equipment will determine the success or failure of your business. In particular, the use of extrusion equipment with excellent kneading and temperature control performance will enable the stable production of high-quality bioplastic products without compromising the characteristics of the material.

Main equipment required for plastics processing

Equipment required for plastics processing includes the following

| device name | role |

|---|---|

| Crushers / Pulverizers | Waste materials and raw materials are reduced in size and made reusable. |

| dryer | Essential for pre-processing of highly hygroscopic materials. |

| Mixers & Weighing Equipment | Adjust the ratio of additives, pigments, etc. to achieve uniformity. |

| extruder | The heart of the production line where raw materials are heated, kneaded, and molded. Available with a single or dual shaft. |

| pelletizer | Cut the extruded material into pellets. |

| Cooling and conveying line | Maintain product shape stability and quality. |

Each of these devices is directly related to process efficiency and quality stability, and all play an important role. Among them,Twin-screw extruders are attracting attention as core equipment that supports business differentiation by increasing the flexibility of materials.It is.

Why twin-screw extruders are key

Strong in high-mix low-volume production

Twin-screw extruders can freely reconfigure the screw configuration to perform a variety of processes. Therefore,Customization can be handled on a case-by-case basis.Another major advantage of twin-screw extruders is that they The ability to make materials suited to customer needs makes it easier to avoid price competition and to secure stable profits.

Works well with reclaimed materials

It is common for recycled materials to have variations in quality, such as contamination and deterioration. With twin-screw extruders, high dispersion reduces unevenness while,Stable processing even with recycled materialsIt is. Now that "small-lot production with design capability" is required rather than mass production, twin-screw extruders can be the key to differentiating our business in this context.

High kneading power

The twin-screw extruder allows pigments and additives to be uniformly dispersed throughout the resin by the interaction of the two screws.Less susceptible to variations in physical properties, even in complex formulationsThe feature of this system is that it is easy to maintain stable quality. It also contributes to the reduction of product complaints and realizes a highly reliable production system.

Actual use case: Small business succeeding with twin-screw extruder

Thailand|Snack startup: Creating hit products in small quantities and in many varieties

A new snack company in Thailand has installed a small twin-screw extruder for food products to produce health-conscious rice puff snacks and corn snacks in a single unit. With a throughput of 350 kg per hour, the machine efficiently produces a wide variety of products in small quantities. The company captured the needs of the local market and achieved profitability in a short period of time.

Key Success Factors

- Flexibility to support multiple products with a single unit

- Automated processing of heating, kneading, and molding saves manpower.

- Ability to develop market-appropriate flavors and shapes

Malaysia|Packaging Manufacturer:Balancing Productivity and Environmental Responsibility

Massive Industries is a small- to medium-sized company that manufactures polyethylene bags. With the introduction of a twin-screw extruder and in-house recycling facilities, the company is able to simultaneously produce multilayer films and utilize recycled materials. The company is expanding its sales channels domestically and internationally to meet the needs for sustainable packaging materials.

Key Success Factors

- Simultaneous 2-line extrusion improves throughput

- Cost reduction through in-house recycling

- Combines thin film thickness accuracy and finish quality

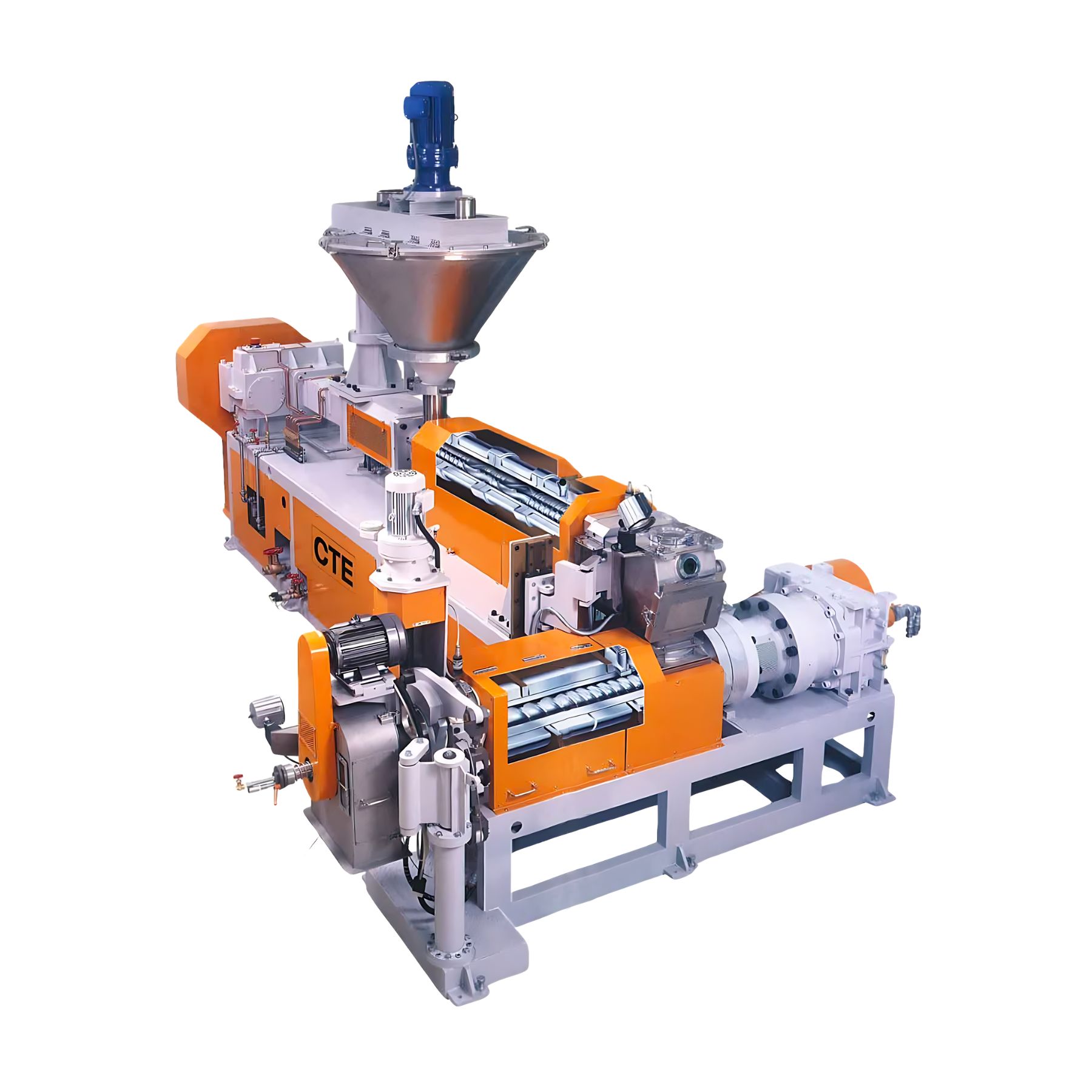

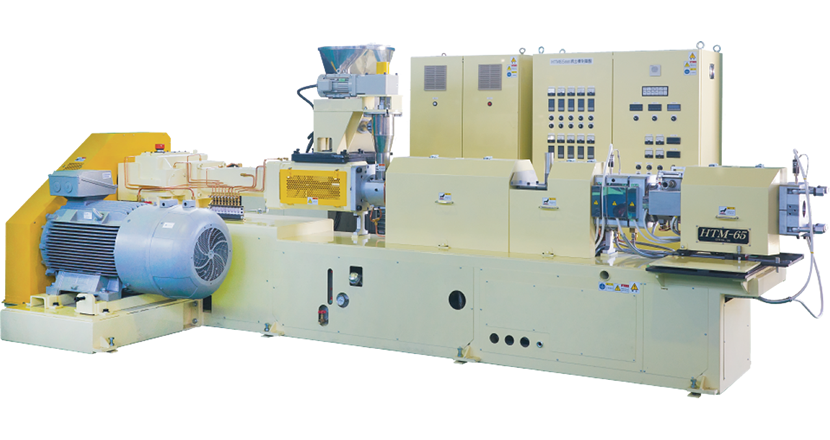

One of CTE's twin-screw extruders, the HTM tandem kneading extruder,High density fillers, recycled materials and biodegradable resinsThis extruder can be used for a wide range of plastic processing applications such as It can also be used for high filler content of inorganic fillers such as talc, calcium carbonate, and titanium dioxide. It is also capable of processing heat- and shear-sensitive resins such as rigid PVC, recycled PVC, and PBAT with minimal degradation and high quality.

Furthermore, due to the unique structure of non-engagement and inter-directional rotation,High outgassing performance prevents bubbles and molding defects in pelletsIt is suitable for use in the chemical/material recycling field. It also has excellent kneadability and dispersibility, making it suitable for use in the chemical and material recycling fields.

The screw configuration is segmented and can be flexibly customized according to material characteristics and purpose. From plastic raw materials to recycled materials and biomass resins,Versatility and productivity for a variety of recipesThis is an extremely effective solution for the plastics business from the

Summary: Material design capabilities are important for the plastics business.

In the plastics business, simply installing equipment is not enough. It is important to,Perspectives on what materials can be designedIt is. If you can propose materials based on your knowledge of materials to suit the application and performance, you will be able to differentiate yourself from your competitors and reduce the risk of getting caught in price competition. Now is an opportune time to strategically examine the business model of plastics x twin-screw extruder.